Top selling product

Factor Automation Components

Miniature Guide Set

In recent year, as ever-changing technology, the demand for Miniature Guide Set in industrial automation has been increasing. In increasingly accuracy product, need smaller, lighter and more powerful components. Any size smaller than 10mm, precision accuracy between 5μm and 20 μm be called Miniature Guide set. Also can called Miniature Stroke.

See the product

Press Mold Components

Precision Guide Post Set

The tolerance of the part size reflects the ease of processing, that means level of processing accuracy, it is the main basis for the development of processing technology.The tolerance range for hole shaft is generally 5 µm. Products below this tolerance, such as 3 µm and 2 µm, are called precision grade.

See the product

Factor Automation Components

Manual Positioning X Axis - Standard

Manual Slide X-axis - HXCRS80 is to utilize rails to restrict the object's movement, allowing it to only travel along a single direction. The rails can be either straight or curved.

See the product

Press Mold Components

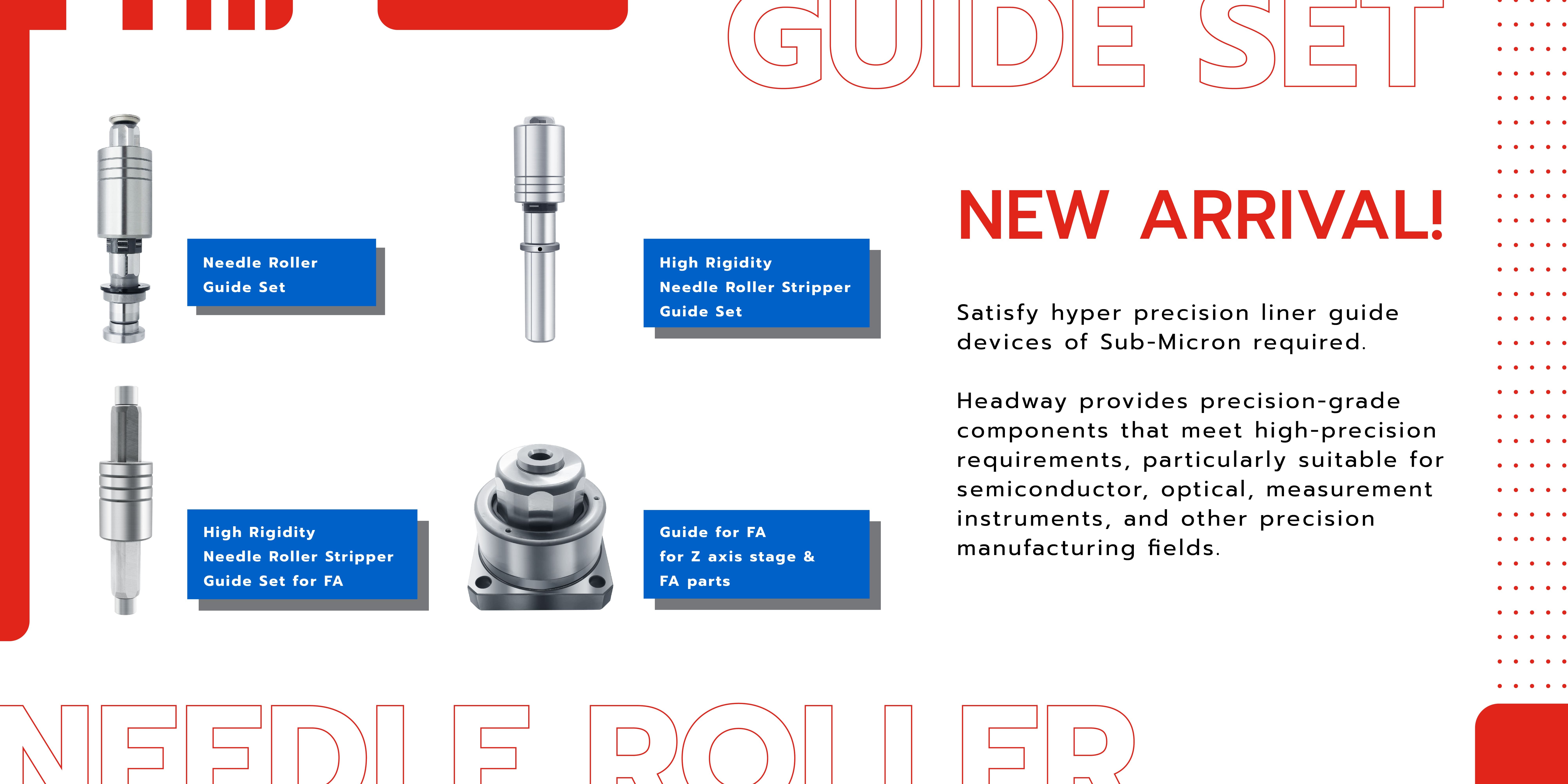

Needle Roller Guide Set

Ultra-high precision linear equipment that meets the needs of submicron (100nm~1μm).High precision and high rigidity are required for the production of optical equipment and semiconductors. Changing the rolling body from a ball to a needle increases the contact surface area to achieve high rigidity, and the ultra-high precision linear guide rail after using a needle reduces impact, friction and vibration when entering, thus achieving high precision and high linearity.

See the product

Factor Automation Components

Ball Screws

It is the action of the steel ball between the nut and the screw. It is the first mechanical component of the transmission which is made by the sliding contact of the traditional screw, modified into the rolling contact, and then converts the rotation of the steel ball inside the nut into the linear motion.

Ball screw has become one of the key components in the precision technology industry and precision machinery industry in recent years because of its high positioning accuracy, long life, low pollution, and the ability to do high-speed forward and reverse transmission and conversion transmission.

See the product

Ball screw has become one of the key components in the precision technology industry and precision machinery industry in recent years because of its high positioning accuracy, long life, low pollution, and the ability to do high-speed forward and reverse transmission and conversion transmission.

Press Mold Components

Needle Roller Guide Set

Ultra-high precision linear equipment that meets the needs of submicron (100nm~1μm).High precision and high rigidity are required for the production of optical equipment and semiconductors. Changing the rolling body from a ball to a needle increases the contact surface area to achieve high rigidity, and the ultra-high precision linear guide rail after using a needle reduces impact, friction and vibration when entering, thus achieving high precision and high linearity.

See the product

Factor Automation Components

Manual Positioning X Axis - Standard

Manual Slide X-axis - HXCRS60 typically comprises a platform and a handle, enabling operators to manipulate the platform by rotating the handle or pressing buttons, achieving precise positioning.

See the product

Factor Automation Components

Manual Positioning X Axis - Standard

Manual slide X-axis - HXCRS40 are ubiquitous equipment in the industrial realm, serving as both a device for moving and positioning workpieces or tools, and a precision positioning mechanism for objects.

See the product

Press Mold Components

Needle Roller Guide Set

Ultra-high precision linear equipment that meets the needs of submicron (100nm~1μm).High precision and high rigidity are required for the production of optical equipment and semiconductors. Changing the rolling body from a ball to a needle increases the contact surface area to achieve high rigidity, and the ultra-high precision linear guide rail after using a needle reduces impact, friction and vibration when entering, thus achieving high precision and high linearity.

See the product

Commitment˙Quality˙Partnership

In an industry driven by numbers, Headway offers a simple and flexible alternative for molds and automation components.

With more than 20 years of experience in trading and its own factory, no matter how complicated or simple your requirements are, Headway is the one-stop shop solution to your component needs.

With more than 20 years of experience in trading and its own factory, no matter how complicated or simple your requirements are, Headway is the one-stop shop solution to your component needs.

Solution

Recent news

2025/09/20

Common problem

-

QWhat is the return/cancellation policy for HEADWAY's products?Open or CloseAYou may cancel any standard order before shipping(Custom orders must be confirmed according to the status of each order).

Orders cannot be returned once shipped unless the item is damaged in transit or the delivered item is incorrect. -

QHow long will I receive my product?Open or CloseACurrently, all of HEADWAY's products are in stock, and domestic customers can receive the products within 24 to 72 hours after placing an order.

;Overseas customers can receive the goods within 2~5 days after placing the order through express delivery service.

;Heavy goods to be delivered by air or sea freight will be delivered within 1 month.

(This will depend on the delivery schedule of each product and the transportation Distribution of the logistics company) -

QDo you offer other brand equivalents?Open or CloseAIf you have a project that requires similar specifications but not necessarily a HEADWAY part number, we can also assist.

As mentioned earlier, HEADWAY is known for the wide range of products it can offer. So, if you need something similar, please let us know,

We will provide you with another equivalent product of the same specification for you to choose.