- Home

- Products

- Factor Automation Components

- Linear Motion Parts

- Miniature Guide Set

- Miniature Stroke Rotary Bushing-KS / KSO / KST / KC / KCO / KCT

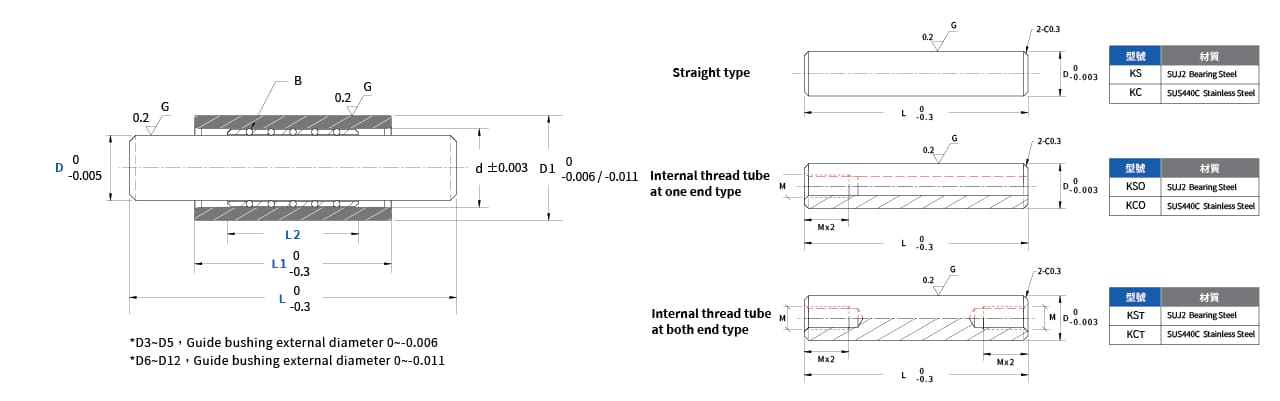

D3~D12˙material SUJ2/SUS440C˙Guide set Straight type-Wall thickness standard type˙Steel Ball Diameter1.0mm˙Guide set shape three option(straight type/One end inner thread type/two ends inner thread type)

- Product Specification

- Product Characteristics

- Why you must choose HEADWAY

| KS | 3 | 40 | 10 | 10 | G5 | W |

|---|---|---|---|---|---|---|

| | | | | | | | | | | | | | |

| Straight type of guide bushing˙Straight type of guide post˙SUJ2 | Guide post external diameter D | Length of guide post L | Length of guide bushing L1 | Length of ball retainer L2 | Steel ball precision | Have backlash |

- Low-friction rotating motion is possible.

- High-precision rotating motion is possible.

- The most basic specification of the miniature guide set.

| Model | Material | ||||

|---|---|---|---|---|---|

| Miniature Guide bushing | Miniature guide post | Guide post+ Guide bushing+ Steel ball | Ball retainer (retainer) |

||

| Straight type | Internal thread tube at one end type | Internal thread tube at both end type | |||

| Straight type | KS | KSO | KST | SUJ2 | Copper alloy |

| KC | KCO | KCT | SUS440C | Copper alloy | |

| D | L (KS/KC)(KSO/KCO) Unit length(1mm) |

L (KST/KCT) Unit length(10mm) |

L1 | L2 | D1 | d | M | B |

|---|---|---|---|---|---|---|---|---|

| 3 | 40~70 | - | 10/20/30 | 10/15/20 | 7 | 5 | - | 1.0 |

| 4 | 40~70 | - | 10/20/30 | 10/15/20 | 8 | 6 | - | |

| 5 | 40~90 | 40~90 | 10/20/30 | 10/15/20 | 10 | 7 | M3 | |

| 6 | 40~90 | 40~90 | 15/20/30 | 15/20/30 | 11 | 8 | M3 | |

| 8 | 40~150 | 40~100 | 15/20/30 | 15/15/20 | 12 | 10 | M4 | |

| 10 | 40~150 | 40~100 | 20/30/40 | 20/30/40 | 16 | 12 | M5 | |

| 12 | 40~150 | 40~100 | 20/30/40 | 20/30/40 | 18 | 14 | M6 |

| Processing items | ||||

|---|---|---|---|---|

| Preload | ||||

| Code | W | Y | B | R |

| Chase processing items | -1 -2 |

0 +1 |

+1 +2 |

+2 +3 |

| Description | Have backlash | Light preload | Medium preload | Heavy preload |

Stroke length and contact length of micro components

The contact length depends on the position of the guide bush, ball bushing and guide rod relative to each other at the end position of the linear movement, distinguishing 2 different modes according to type:

| 1. Open guide bushing STROKE Series and MINI STROKE Series The steel ball bushing length L2 is greater than or equal to the guide bushing length L1 Maximum stroke linear motion: S=2*(L2-L1) |

|

| 2. Closed (integrated) guide bushing CLOSED series The length of the guide bushing L1 is greater than the length of the ball bushing L2 The steel ball bushing is a special integrated design fixed in the guide bushing. Maximum stroke linear motion: S=2*(L1-L2) |

|

Steel ball accuracy list

| Grade | Applicable range of steel ball size | Steel ball diameter change (VDWS) | True sphericity (SPH) | Surface roughness(RA) | Batch diameter variation (VDWL) | Ball gauge interval | ball gauge value |

|---|---|---|---|---|---|---|---|

| 3 | 0.3mm~12mm | 0.08 | 0.08 | 0.010 | 0.13 | 0.5 | -5,...,-0.5,0,+0.5,...,+5 |

| 5 | 0.3mm~12mm | 0.13 | 0.13 | 0.014 | 0.25 | 1 | -5,...,-1, 0,+1,...,+5 |

| 10 | 0.3mm~25mm | 0.25 | 0.25 | 0.020 | 0.5 | 1 | -9,...,-1, 0,+1,...,+9 |

| 16 | 0.3mm~25mm | 0.4 | 0.4 | 0.025 | 0.8 | 2 | -10,...,-2, 0,+2,...,+10 |

| 20 | 0.3mm~38mm | 0.5 | 0.5 | 0.032 | 1 | 2 | -10,...,-2, 0,+2,...,+10 |

| 24 | 0.3mm~38mm | 0.6 | 0.6 | 0.040 | 1.2 | 2 | -12,...,-2, 0,+2,...,+12 |

| 28 | 0.3mm~38mm | 0.7 | 0.7 | 0.050 | 1.4 | 2 | -12,...,-2, 0,+2,...,+12 |

| 40 | 0.3mm~50mm | 1 | 1 | 0.060 | 2 | 4 | -16,...,-4, 0,+4,...,+16 |

| 60 | 0.3mm~65mm | 1.5 | 1.5 | 0.080 | 3 | 5 | -25,...,-5, 0,+5,...,+25 |

| 100 | 0.3mm~65mm | 2.5 | 2.5 | 0.100 | 5 | 10 | -40,...,-10,0,+10,...,+40 |

| 200 | 0.3mm~65mm | 5 | 5 | 0.150 | 10 | 15 | -60,...,-15,0,+15,...,+60 |

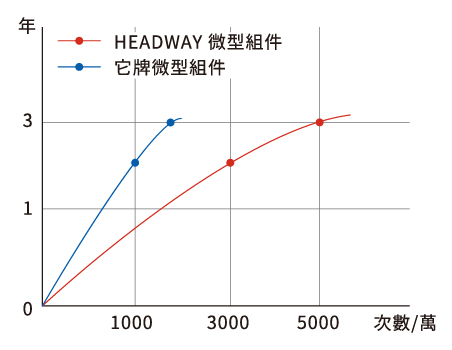

Actual measurement analysis of micro components

Actual Measurement Analysis - Operational Efficiency

The micro-components in the measuring equipment are shown in Table 2-4-1. Under normal use conditions, excluding major equipment damage and human negligence,

their lifespan is approximately between 2 and 3 years without interruption. It can operate up to 30 to 50 million times, and its operating efficiency is 3 times higher than other brands.

The advantages of choosing HEADWAY micro components are shown in Figure 2-4-2, which include high precision, low wear rate, and greatly extended service life.

| time/year | 24hr/total time | Number of runs | |

|---|---|---|---|

| HEADWAY micro components | Micro components | ||

| 2 | 17520 | 30 million | 10 million |

| 3 | 26280 | 50 million | 18 million |

| ... | ... | ... | ... |

| Tech Tips: HEADWAY micro components can be used without lubricants. For example, in the food industry, optical fields and high vacuum environments, it is recommended to use SUS440C stainless steel for applications. |

HEADWAY presents you with superior quality, firm commitment, and a spirit of partnership. As a manufacturer of automation and mold components, we possess deep knowledge of automation and mold technology, continuously innovating and improving to ensure outstanding performance and reliability.

On the official HEADWAY website, you can not only browse product catalogs but also understand that each product represents our commitment to quality and our responsiveness to customer needs. We rigorously control the manufacturing process, utilizing high-quality materials and precision machining to ensure that every product meets your expectations.

(1).Streamlined Production

(2).No minimum order quantity, we can produce even one.

(3).100% inspection - From production to inspection equipment, all steps are completed by HEADWAY.

(4).Accept custom processing inquiries based on provided drawings.

(5).For product issues and subsequent after-sales service, we provide personalized assistance for you.