Belt and pulley systems are mechanical transmission systems used to transfer power from one rotating wheel-like component to another. Belts, made from flexible materials like rubber or synthetic materials, are belt-like objects that snugly wrap around the surface of the pulleys. When the pulley receiving the power rotates, the belt follows due to friction, transmitting the power to another pulley. This way, power is transferred from one wheel-like component to another, driving machinery or facilitating movement between different parts.

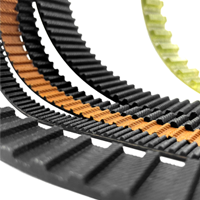

Belt and pulley systems come in various types, each with specific characteristics and applications.

- Timing Belts: Ensure precise synchronous transmission by meshing gears with belt teeth, commonly used in industrial applications that require precise timing relationships.

- V-Belts: Provide frictional traction on rolling elements through their V-shaped structure, used for power transmission and connecting mechanical components.

- Other Industrial Transmission and Conveyor Belts: Please consult with our business for information about specific belt models.

Belt and pulley systems find extensive use across various industrial sectors and machinery due to their efficiency, flexibility, reliability, and cost-effectiveness, making them an ideal solution for power transmission. Achieving efficient, stable, and safe power transmission, as well as maintenance and replacement, is relatively straightforward.

- Automotive Industry: Power transmission in automotive engines, generator drives, etc.

- Industrial Machinery: Power transmission in a wide range of industrial machinery and equipment.

- Agricultural Machinery: Power transmission in agricultural machinery equipment.

- Construction Engineering: Power transmission in construction machinery equipment, such as concrete mixers.

- Mining and Quarrying: Power transmission in mining and quarrying equipment.

- Transportation and Logistics: Power transmission in conveyor belt systems.

- Timing Belts: Efficient synchronous transmission, accurate speed control, less maintenance requirement, and stability under high load and high-speed conditions.

- V-Belts: Good frictional performance, stable operation, easy installation and maintenance, strong adaptability, suitability for high-power and high-speed operation, as well as suppression of mechanical vibration and noise.

- Other Industrial Transmission and Conveyor Belts: Please inquire with our business for details about various versatile belt options.