- Home

- Products

- Factor Automation Components

- Stages

- Manual Stages

- Manual Positioning X Axis - Standard

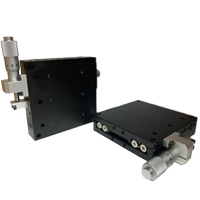

- Manual Slide X-axis - HXCRS80

- Product Specification

- Product Characteristics

- Why you must choose HEADWAY

| Model number | Specifications | Countertop size (MM) | Stroke | Load(N) | Maximum holding force (reference) | Accuracy (MM) | Weight (KG) | Moment load (N,M) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Horizontal | Vertical | Straightness | Parallelism | Up and down | Left and right | Sidewise | ||||||

| HXCRS80 | 80 | 80*80 | ±6.5 | 90 | 45 | 60 | 0.03 | 0.03 | 0.39 | 19.2 | 15.1 | 17.3 |

- The main body is made of aluminum alloy to achieve lightweight.

- The sliding table can be fine-tuned in multiple directions to suit different usage environment requirements.

- Minimum reading of micrometer knob: 10µm/scale

- Smooth sliding and high linear precision. High wear-resistant shaft steel cross guide rail, longer durability.

- The surface of the body is treated with black anodization, which can effectively prevent light reflection and is especially suitable for the optical field.

| Centicali probe position change | ||||

|---|---|---|---|---|

| CR The left and right directions of the sides are different |

A Center |

AR The left and right directions of the center are different |

AZ The center has different up and down directions |

AZR The left, right, and bottom directions of the center are different |

|

|

|

|

|

Manual linear slides are ubiquitous equipment in the industrial realm, serving as both a device for moving and positioning workpieces or tools, and a precision positioning mechanism for objects. They typically comprise a platform and a handle, enabling operators to manipulate the platform by rotating the handle or pressing buttons, achieving precise positioning. While the operation principle of manual linear slides is relatively straightforward, safety and accuracy must be prioritized in practical applications.

Fundamental Concepts:

The underlying principle of manual linear slides is to utilize rails to restrict the object's movement, allowing it to only travel along a single direction. The rails can be either straight or curved. The platform of a manual linear slide is commonly constructed from metal or plastic, and its dimensions and shape can be customized based on the specific application.

Operational Steps:

- Preparation: Ensure the manual linear slide and workspace are clean and free of obstructions.

- Equipment Inspection: Verify that the handle or buttons function properly, the platform moves smoothly, and there are no signs of jamming.

- Position Adjustment: Adjust the position of the manual linear slide according to the size and positional requirements of the workpiece or tool.

- Platform Movement: Rotate the handle or press the buttons to move the platform along the rail to the desired position.

- Positioning Confirmation: Once in the target position, check if the platform is accurately aligned.

Application Analysis:

- Manual linear slides are suitable for scenarios that demand the movement and positioning of workpieces or tools, such as assembly lines and machining equipment in manufacturing industries.

- Laboratories: Manual linear slides can be employed to position microscope specimens or other laboratory equipment.

- Factories: They find application in positioning machine tools workpieces or other components.

- Optical Instruments: Manual linear slides are used to adjust the position of optical elements.

- Electronic Devices: They are utilized for positioning circuit boards or other components.

- Medical Devices: Manual linear slides play a role in positioning surgical instruments or other equipment.

- Precision Machinery: They are employed for precise positioning of components in other precision machinery.

Advantages:

- Simple structure, facilitating manufacturing and maintenance.

- Low cost.

- High precision.

- Ease of use.

HEADWAY is presented to you with excellent quality, firm commitment and the spirit of partnership. As a manufacturer of automation and mold components, we are well versed in automation and mold technology, and we continue to innovate and improve to ensure that our products perform well in terms of performance and reliability.

On the official website of HEADWAY, you can not only browse the product catalog, but each product represents our commitment to quality and response to customer needs. We strictly control the manufacturing process, use high-quality materials and perform precision machining to ensure that each product perfectly meets your expectations.

When purchasing a slide table, the following factors should be considered:

Precision Requirement: Choose a slide table with suitable precision according to application requirements.

Load Capacity: Select a slide table with appropriate load capacity based on the weight of the object to be moved.

Movement Speed: Choose a slide table with suitable movement speed according to application requirements.

Control Method: Select a slide table with suitable control method based on application requirements.

Structural Form: Choose a slide table with suitable structural form according to application requirements.

1.Requirements Analysis: Determine the size and functional requirements of the manual linear slide based on production needs.

2.Equipment Selection: Choose an appropriate manual linear slide model based on the requirements.

3.Installation and Debugging: Install the manual linear slide and perform functional debugging to ensure proper operation.

4.Operator Training: Train operators on the operation methods and precautions for the manual linear slide.

5.Monitoring and Maintenance: Regularly inspect and maintain the manual linear slide to ensure its long-term stable operation.