- Home

- Products

- Factor Automation Components

- Linear Motion Parts

- Ball Screws

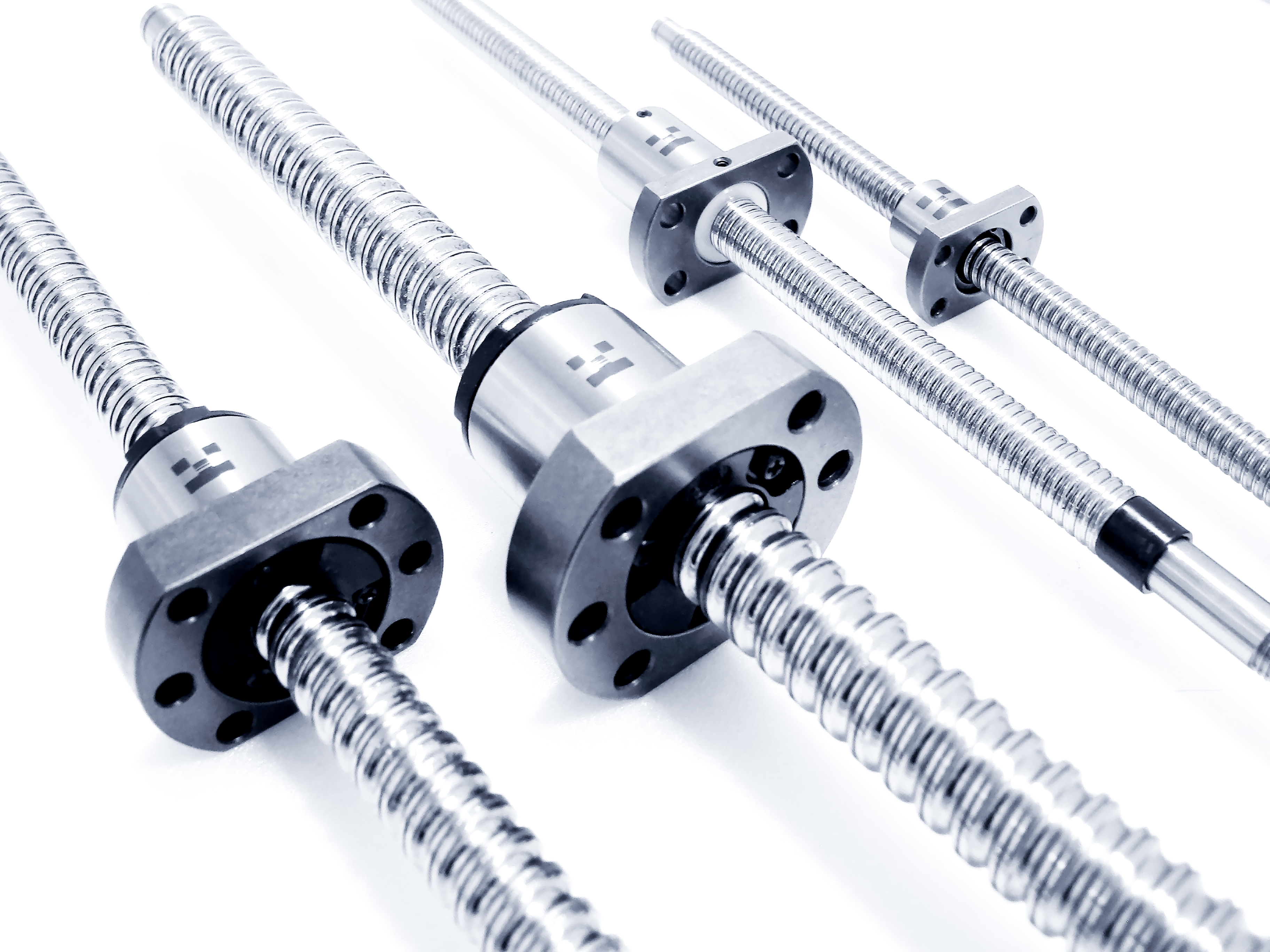

- Miniature Ball Screws-SFT

C10˙Shaft diameter lead 0802~1004˙Inner circulation˙End plug type micro diameter nut

- Product Specification

- Product Characteristics

- Why you must choose HEADWAY

| S | F | T | 08 | 02 | P0 | F | C7 | 244 | R | 29 | UN |

|---|---|---|---|---|---|---|---|---|---|---|---|

| | | | | | | | | | | | | | | | | | | | | | | | |

| S:Single nut | S:Square type | V:External Circulation | Shaft diameter | Lead | P0:No preload, with backlash | G:Grinding | Precision | Effective thread | R:Right thread | Total Length | Shaft end unprocessed |

| D:Double nuts | R:Round type | C:End plug standard type | P1:No preload, no backlash | F:Rolled | L:Left thread | ||||||

| F:Flange type | T:End plug type micro-diameter type | P2:Light preload, no backlash | |||||||||

| P3:Medium preload, no backlash | |||||||||||

| P4:Heavy preload, no backlash |

- The economical model can meet most of the feeding devices.

- The micro-diameter type saves a lot of space in the organization.

- Lower profile linear units can be designed by using in combination with Support Units Low Profile Type.

- Conforms to JIS (ISO) accuracy standards.

- Standards dimensions in stock.

- Oil inlet on the nut, easily use while assembling and maintaining.

| Ball Screw Specification | |

|---|---|

| Precision | C10 |

| Circulation method | End plug type micro-diameter type |

| Axial backlash / preload level | P0:No preload, with backlash |

| Screw Material | S55C |

| Nut Material | SCMA15H |

| Spiral Direction | Right Thread |

| Using Grease | Alvania S2 |

| Model | Outer diameter | Lead | Screw Specification | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | P | D1 | D2 | D3 | D4 | D5 | D6 | D7 | S | N | M | R | |||

| SFT0802 | 08 | 2 | 100~400 | L1-46 | 29.5 | 9 | 0.8 | 6.8 | 7.5 | 8 | 4.5 | 6 | 6 | 5.7 | 9.5 | 6 | 7 | 7 | M6x0.75 | Less than 0.3 |

| SFT1002 | 10 | 4 | 150~585 | L1-54 | 35 | 9 | 0.8 | 6.8 | 10 | 10 | 6 | 8 | 6 | 5.7 | 10 | 8 | 8 | 9 | M8x1.0 | Less than 0.3 |

| SFT1204 | 12 | 4 | 150~600 | L1-54 | 35 | 9 | 0.8 | 6.8 | 10 | 10 | 6 | 8 | 6 | 5.7 | 10 | 8 | 8 | 9 | M8x1.0 | Less than 0.3 |

| Nut Specification | Core diameter | BCD | Recurring decimal | Reted load(N) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | DA | DB | H | PCD | X | Y | Z | T | Ball diameter | Dynamic load Ca | Static load Coa | ||

| 16 | 4 | 12 | 27 | 14 | 18 | 21 | 3.4 | - | - | - | 7.21 | 8.41 | 3x1 | 1200 | 2100 |

| 1.2 | |||||||||||||||

| 28 | 5 | 23 | 35 | 18 | 22 | 27 | 4.5 | - | - | - | 9.21 | 10.41 | 3x1 | 1200 | 2100 |

| 1.2 | |||||||||||||||

| 34 | 10 | 24 | 46 | 26 | 28 | 36 | 4.5 | 8 | 4.5 | M6x1.0 | 8.4 | 10.5 | 3x1 | 1870 | 3000 |

| Code | MC | EC | FC | NC | RLC |

|---|---|---|---|---|---|

| Processing content |  |

|

|

|

|

| Description | Processing of support side shaft end screw thread hole (Specified unit:1mm) Representation:MC15 |

Specified processing of support side shaft end but not processing buckle groove Representation:EC-Q20-E20 |

Specified processing of support side shaft end and processing buckle groove Representation:FC-Q10-E20 |

No processing support side Representation:NC |

Nut assembly direction change Representation:RLC |

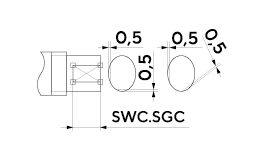

| Code | KC | KLC | SC | SWC & SGC | SZC |

|---|---|---|---|---|---|

| Processing content |  |

|

|

|

|

| Description | Key groove processing at fixed end Representation:KC15 |

Key groove processing at fixed end Representation:KLC-K10-S2 |

At the shaft end of fixed side flat processing Representation:SC5 |

At the shaft end of fixed side doing two desk surface processing Representation:SWC6,SGC6 |

At the shaft end of fixed side wrench groove processing Representation:SZC(you can see the picture) ※Only use for rolled screws |

|

||

| Processing shaft diameter | W -0.004 -0.029 |

H +0.1 0 |

|---|---|---|

| 6~7 | 2 | 1.2 |

| 8~10 | 3 | 1.8 |

| 11~12 | 4 | 2.5 |

| 13~17 | 5 | 3 |

| 18~20 | 6 | 3.5 |

|

|||

| Processing shaft diameter | SZC ±0.1 |

S ±0.1 |

H 0 -0.2 |

|---|---|---|---|

| 8 | 4 | 4 | 5 |

| 10 | 5 | 5 | 8 |

| 12 | 5 | 5 | 8 |

| 15 | 7 | 5 | 10 |

| 20 | 9 | 6 | 16 |

| 25 | 10 | 7 | 18 |

|

|

| Screw outer diameter | MXPX effective thread |

|---|---|

| 8 | M2.5XP0.45X6L |

| 10 | M3XP0.5X8L |

| 12 | M3XP0.5X8L |

| 15 | M5XP0.8X12L |

| 16 | M5XP0.8X12L |

| 20 | M6XP1.0X15L |

| 25 | M8XP0.25X20L |

Shaft end accuracy standard

Grinding Grade Ball Screw |

|

| (1)˙(2) (3) (4)˙(5) (6) (7) (8) |

Circular vibration generated in the radial direction of the thread surface corresponding to the axis of the screw shaft support part. This item includes the influence of the full vibration of the screw axis in the back-radial direction of item (8), so sometimes corrections must be made. The radial direction of the component mounting portion corresponding to the axis of the support portion of the screw shaft vibrates circumferentially. The end face of the support part corresponding to the axis of the support part of the screw shaft must be at a right angle. The axis of the screw shaft corresponds to the right angle of the base end face of the nut or the flange mounting surface. The axis of the screw shaft corresponds to a circular vibration in the radial direction around the outer periphery of the nut. Full vibration of the screw shaft. |

| Form | type | C3 | C5 | C7 | C10 | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shaft diameter | 08 | 10 | 12 | 15 | 20 | 25 | 08 | 10 | 12 | 15 | 20 | 25 | 08 | 10 | 12 | 15 | 20 | 25 | 08 | 10 | 12 | 15 | 20 | 25 | |

| (1)(2) Deflection tolerance (Max) |

0.008 | 0.009 | 0.010 | 0.010 | 0.011 | 0.012 | 0.013 | 0.014 | 0.020 | 0.040 | 0.060 | ||||||||||||||

| (3)Deflection tolerance (Max) | 0.008 | 0.009 | 0.010 | 0.010 | 0.011 | 0.012 | 0.013 | 0.014 | 0.020 | 0.040 | 0.060 | ||||||||||||||

| (4)(5)Right angle tolerance(Max) | 0.004 | 0.005 | 0.007 | 0.010 | |||||||||||||||||||||

| (6)Right angle tolerance(Max) | 0.008 | 0.010 | 0.011 | 0.013 | 0.014 | 0.018 | - | ||||||||||||||||||

| (7)Deflection tolerance (Max) | 0.009 | 0.010 | 0.012 | 0.015 | 0.019 | 0.020 | 0.030 | - | |||||||||||||||||

Reinforced grade ball screw |

|

| Lead accuracy | |||||

|---|---|---|---|---|---|

| Effective stroke length | Accuracy level | ||||

| Above | The following | C3 | C5 | ||

| Cumulative error | Single groove error | Cumulative error | Single groove error | ||

| - | 315 | 12 | 8 | 23 | 18 |

| 315 | 400 | 13 | 10 | 25 | 20 |

| 400 | 500 | 15 | 10 | 27 | 20 |

| 500 | 630 | 16 | 12 | 30 | 23 |

| 630 | 800 | 18 | 13 | 35 | 25 |

| 800 | 1000 | 21 | 15 | 40 | 27 |

| 1000 | 1250 | 24 | 16 | 46 | 30 |

| 1250 | 1600 | 29 | 18 | 54 | 35 |

單位:mm

| Accuracy level | C3 | |||||

|---|---|---|---|---|---|---|

| Screw shaft outer diameter | Exceed | - | 8 | 12 | 20 | |

| The following | 8 | 12 | 20 | 32 | ||

| Overall length of screw shaft | Exceed | The following | Vibration tolerance | |||

| - | 125 | 0.025 | 0.025 | 0.020 | - | |

| 125 | 200 | 0.035 | 0.035 | 0.025 | 0.020 | |

| 200 | 315 | 0.050 | 0.040 | 0.030 | 0.030 | |

| 315 | 400 | 0.060 | 0.050 | 0.040 | 0.035 | |

| 400 | 500 | 0.065 | 0.050 | 0.040 | ||

| 500 | 630 | 0.070 | 0.055 | 0.045 | ||

| 630 | 800 | 0.070 | 0.055 | |||

| 800 | 1000 | 0.095 | 0.065 | |||

| 1000 | 1250 | 0.120 | 0.085 | |||

Unit: mm

| Accuracy level | C5 | |||||

|---|---|---|---|---|---|---|

| Screw shaft outer diameter | Exceed | - | 8 | 12 | 20 | |

| The following | 8 | 12 | 20 | 32 | ||

| Overall length of screw shaft | Exceed | The following | Vibration tolerance | |||

| - | 125 | 0.035 | 0.035 | 0.035 | - | |

| 125 | 200 | 0.050 | 0.040 | 0.040 | 0.035 | |

| 200 | 315 | 0.065 | 0.055 | 0.045 | 0.040 | |

| 315 | 400 | 0.075 | 0.065 | 0.055 | 0.045 | |

| 400 | 500 | 0.080 | 0.060 | 0.050 | ||

| 500 | 630 | 0.090 | 0.075 | 0.060 | ||

| 630 | 800 | 0.090 | 0.070 | |||

| 800 | 1000 | 0.120 | 0.085 | |||

| 1000 | 1250 | 0.150 | 0.100 | |||

Unit: mm

| Accuracy level | C7 | |||||

|---|---|---|---|---|---|---|

| Screw shaft outer diameter | Exceed | - | 8 | 12 | 20 | |

| The following | 8 | 12 | 20 | 32 | ||

| Overall length of screw shaft | Exceed | The following | Vibration tolerance | |||

| - | 125 | 0.060 | 0.055 | 0.060 | - | |

| 125 | 200 | 0.075 | 0.065 | 0.070 | - | |

| 200 | 315 | 0.100 | 0.080 | 0.080 | 0.060 | |

| 315 | 400 | 0.100 | 0.095 | 0.070 | ||

| 400 | 500 | 0.120 | 0.110 | 0.080 | ||

| 500 | 630 | 0.150 | 0.140 | 0.090 | ||

| 630 | 800 | 0.170 | 0.100 | |||

| 800 | 1000 | 0.210 | 0.130 | |||

| 1000 | 1250 | 0.270 | 0.150 | |||

| 1250 | 1600 | 0.190 | ||||

| 1600 | 2000 | |||||

Unit: mm

HEADWAY presents you with superior quality, firm commitment, and a spirit of partnership. As a manufacturer of automation and mold components, we possess deep knowledge of automation and mold technology, continuously innovating and improving to ensure outstanding performance and reliability.

On the official HEADWAY website, you can not only browse product catalogs but also understand that each product represents our commitment to quality and our responsiveness to customer needs. We rigorously control the manufacturing process, utilizing high-quality materials and precision machining to ensure that every product meets your expectations.

(1).Streamlined Production

(2).No minimum order quantity, we can produce even one.

(3).100% inspection - From production to inspection equipment, all steps are completed by HEADWAY.

(4).Accept custom processing inquiries based on provided drawings.

(5).For product issues and subsequent after-sales service, we provide personalized assistance for you.