- Product Specification

- Product Characteristics

- Why you must choose HEADWAY

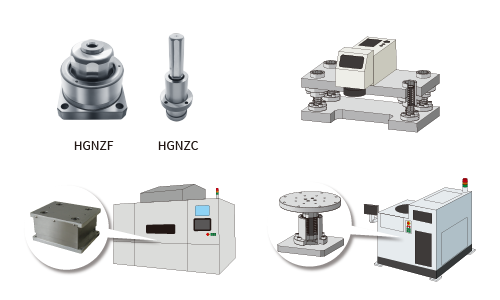

| HGNZF | 12 | 50 |

|---|---|---|

| | | | | | |

| Model | External diameter of Guide Post D | Length of Guide Post L |

- The rigidity of the line contact rolling pins provide rigidity over 10 times greater.

- Straightness exceeds 2 times.

- Rolling pins distribute pressure, extending service life.

- Low vibration enables low pre-loading.

- High precision, repeatability exceeds 3 times.

| Component | ||

|---|---|---|

| Name | Material | Hardness |

| ① Guide Post | SKS3 | 60~62 HRC |

| ② Guide Bushing | SKS3 | 60~62 HRC |

| ③ Needle Roller Retainer | Needle(POM):SUJ2 | - |

| Retainer: Super Engineering Plastic | ||

| Optional Part | ||

| ④ Fixed Stopper | S45C | - |

| ⑤ Spring | SWP-B | |

| D | L | ① Guide post | ② Guide bushing | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Effective stroke | D1 | H | PCD | M×ℓ | D3 | D2 | PCD1 | L1 | H1 | ød1 | ||

| 12 | 50~120 | 20 | 30.0 | 7.0 | 22 | - | 40 | 23 | 32.0 | 40 | 7.0 | 4.4 |

| 16 | 80~140 | 20 | 36.0 | 9.0 | 27 | - | 48 | 30 | 39.5 | 40 | 9.0 | 5.5 |

| 20 | 80~140 | 16 | 41.0 | 9.0 | 31.5 | - | 56 | 37 | 47.5 | 60 | 9.0 | 5.5 |

| 25 | 100~210 | 16 | 48.0 | 12.0 | 37 | - | 67 | 44 | 56.0 | 70 | 12.0 | 6.5 |

| 28 | 100~210 | 18 | 51.0 | 12.0 | 40 | - | 70 | 47 | 59.0 | 75 | 12.0 | 6.5 |

| 30 | 100~210 | 20 | 53.0 | 13.0 | 42 | - | 73 | 50 | 62.0 | 78 | 13.0 | 6.5 |

| 35 | 120~220 | 24 | 58.0 | 13.0 | 47 | 10×25 | 82 | 58 | 71.0 | 86 | 13.0 | 6.5 |

| 40 | 120~220 | 28 | 70.0 | 15.0 | 56 | 12×30 | 97 | 68 | 83.5 | 92 | 15.0 | 8.5 |

| 50 | 160~250 | 28 | 82.0 | 15.0 | 68 | 12×30 | 107 | 78 | 93.5 | 96 | 15.0 | 8.5 |

| 60 | 160~250 | 28 | 97.0 | 18.0 | 80 | 14×30 | 134 | 95 | 117.0 | 120 | 18.0 | 11.0 |

| ③ Needle Roller Retainer | ④ Fixed stopper | ⑤ Spring | ||||||

|---|---|---|---|---|---|---|---|---|

| RL | ød | L1 | Amount of Needle | D3 | D4 | L3 | M | SL |

| 30 | 2.0 | 4.8 | 45 | - | - | - | - | 30~100 |

| 30 | 2.0 | 6.8 | 24 | 17.5 | 14.4 | 14 | 6 | 30~100 |

| 52 | 2.0 | 6.8 | 57 | 21 | 18 | 23 | 8 | 40~100 |

| 62 | 2.0 | 7.8 | 69 | 24 | 23 | 28 | 8 | 55~125 |

| 66 | 2.5 | 7.8 | 57 | 30 | 25.5 | 30 | 8 | 55~145 |

| 68 | 2.5 | 7.8 | 57 | 32 | 27.5 | 31 | 10 | 50~160 |

| 74 | 2.5 | 9.8 | 69 | 37 | 32.5 | 34 | 10 | 65~175 |

| 78 | 3.0 | 9.8 | 75 | 43 | 38 | 36 | 12 | 70~170 |

| 82 | 3.0 | 11.8 | 78 | 52.5 | 47.5 | 38 | 12 | 90~200 |

| 116 | 4.0 | 13.8 | 84 | 64.5 | 57.5 | 54 | 14 | 100~200 |

Flange type Z-axis guide: the most suitable for elevating stage

Shaft diameter ∅60~80

Inspection Devic

High rigidity and low vibration make the camera statically determinate quicker, and lead to shorter cycle time.

Precision Z stage for the exposure equipment

Accuracy improvement enables sub-micron order positioning.

Z stage for the prober

Higher guide rigidity reduces the deflection caused by the offset load on the stage.

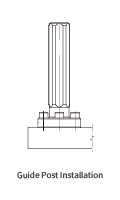

Installation Method

1、Processing of installation holes for Guide posts and bushing

Tap 4-ØZPP, ØZBP at the post & the bush installation plate. Confirm the PCD and PCD1 according to the product size.

| Product Name | Screw Hole |

|---|---|

| HGNZF·HGNZC 12 | M4 |

| HGNZF·HGNZC 16 | M5 |

| HGNZF·HGNZC 20 | |

| HGNZF·HGNZC 25 | M6 |

| HGNZF·HGNZC 28 | |

| HGNZF·HGNZC 30 | |

| HGNZF·HGNZC 35 | |

| HGNZF·HGNZC 40 | M8 |

| HGNZF·HGNZC 50 | |

| HGNZF·HGNZC 60 | M10 |

2、Post installation

- Determine the counter mark direction for easy recognition.

- Fix the post to the installation hole of the plate with the specific bolts.

- The post perpendicularity must be checked (0.01mm/100mm or less)

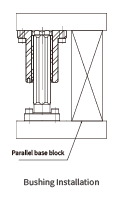

3、 Bush installation

- Combine the post and the bush. Make sure the counter marks and the specific numbers are correspondent.

- Place the parallel base block on the plate of the post side, put the plate of the bush side on it and fit it to the installation hole.

- Fix the bush to the plate with the specific bolts.

The Significance of Electrode Stamping Technology in Electric Vehicle Battery Manufacturing

In the production process of electric vehicle batteries, electrode stamping technology plays a crucial role. Electrodes, as the core components of batteries, directly influence the capacity, energy density, and lifespan of batteries. Electrode stamping technology is one of the key processes for manufacturing battery electrodes. Its main function is to stamp electrode materials into the required shapes and sizes.

Traditional electrode stamping technology mainly employs manual pulling methods, resulting in low production efficiency, poor product precision, and safety risks. These limitations hinder the fulfillment of modern industrial demands and lead to low production benefits and increased costs for enterprises. To address these issues, automated electrode stamping and pulling devices have been developed.

Key to Enhancing Electrode Stamping Technology Precision

The key to enhancing electrode stamping technology precision lies in utilizing high-precision guide rails. Guide rails are essential components in electrode stamping and pulling devices. Their primary function is to guide and support the electrode materials along a specified trajectory during the stamping process.

HEADWAY Precision Linear Guide Rail Assemblies for Dies offer a high-precision guide rail solution, achieving a precision level of up to 0.1 µm, far surpassing traditional guide rails. Implementing HEADWAY Precision Linear Guide Rail Assemblies for Dies effectively elevates electrode stamping technology precision, further improving battery performance.

Advantages of HEADWAY Precision Linear Guide Rail Assemblies for Dies

HEADWAY Precision Linear Guide Rail Assemblies for Dies provide an efficient and precise solution to the aforementioned challenges. These guide rail assemblies incorporate advanced high-precision rolling technology, specifically designed for submicrometer-level process requirements. They are particularly well-suited for applications in electrode stamping processes that demand extreme precision and stability.

- Ultra-high Precision: The design and manufacturing of the guide rail assemblies ensure a stamping precision of 0.03 µm, significantly enhancing the precision and consistency of electrode manufacturing.

- Smooth Movement: Employing ultra-fine processing technology, the surface of the guide rails is smooth and friction-free, guaranteeing stable movement and high efficiency during the electrode stamping process.

- Reduced Vibration: The polygonal structure design of the guide rails effectively reduces potential vibrations during the stamping process, further improving product processing quality and production efficiency.

HEADWAY Precision Linear Guide Rail Assemblies for Dies are widely applied in electrode stamping and pulling devices, effectively enhancing electrode stamping technology precision and efficiency.

HEADWAY: Your Choice for Enhanced Production Efficiency and Product Quality

HEADWAY Precision Linear Guide Rail Assemblies for Dies not only address the precision and efficiency issues prevalent in traditional electrode stamping technology but also significantly elevate the safety and sustainability of battery production. Choosing HANDEWAY's professional guide rail solutions is your optimal choice for enhancing production efficiency and product quality.

For further information on HEADWAY Precision Linear Guide Rail Assemblies for Dies and model recommendations for various applications, please feel free to contact our professional team. We are committed to providing you with the highest quality technical support and solutions.

HEADWAY presents you with superior quality, firm commitment, and a spirit of partnership. As a manufacturer of automation and mold components, we possess deep knowledge of automation and mold technology, continuously innovating and improving to ensure outstanding performance and reliability.

On the official HEADWAY website, you can not only browse product catalogs but also understand that each product represents our commitment to quality and our responsiveness to customer needs. We rigorously control the manufacturing process, utilizing high-quality materials and precision machining to ensure that every product meets your expectations.

(1).Streamlined Production

(2).No minimum order quantity, we can produce even one.

(3).100% inspection - From production to inspection equipment, all steps are completed by HEADWAY.

(4).Accept custom processing inquiries based on provided drawings.

(5).For product issues and subsequent after-sales service, we provide personalized assistance for you.