Structures and Applications of High Rigidity Needle Roller Stripper Guide Set for FA

2025/11/10

# Article

Structures and Applications of High Rigidity Needle Roller Stripper Guide Set for FA

Features

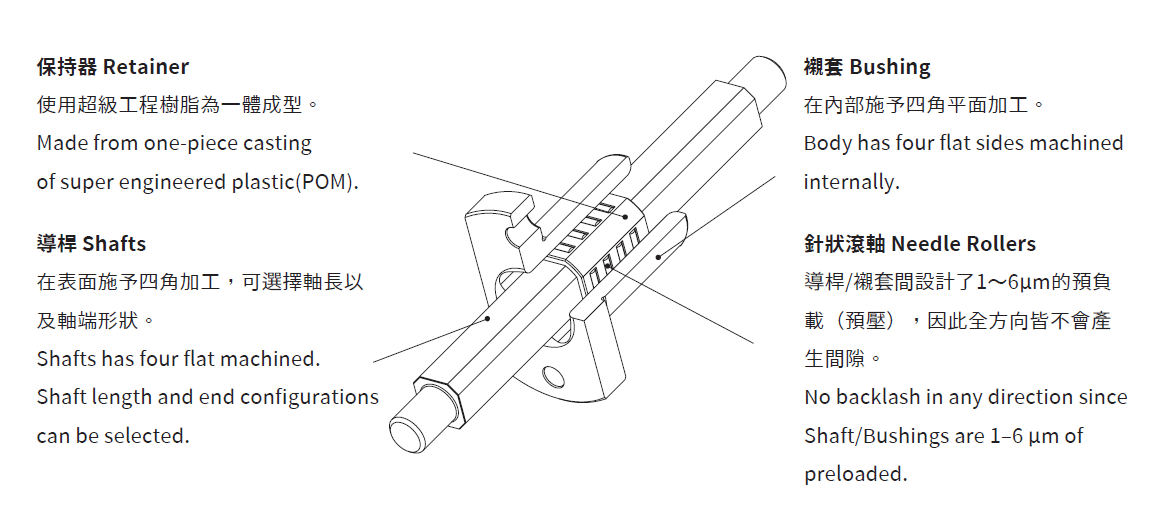

High accuracy needle rollers are arranged in four directions against the square shafts. Shafts / Bushings are designed to be 1‒6 μm preloaded.

Widely used in parts of semiconductor, liquid crystal manufacturing equipment and inspection device, lift/slide stages, robotic systems, press machines and transfer mechanism as the guide with high rigidity, straightness and high speed.

Capable of torque loading without rotation due to square cross section with low yawing and pitching, maintaining smooth rotation and stable accuracy.

| Engineering Plastic | Description | Density (g/cm³) | Tensile Strength (MPa) | Elastic Modulus (MPa) | Heat Deflection Temperature(°C) | Temperature Range(°C) | Impact Strength(J/m) | Electrical Insulation | Chemical Resistance | Applications |

|---|---|---|---|---|---|---|---|---|---|---|

| Polyoxymethylene | High rigidity, excellent impact resistance and wear resistance | 1.41 | 70-100 | 2800-3500 | 90-130 | -40 to 100 | 200-300 | Good | Good | Precision Parts, Automotive |